With the development of technology, people have increasingly higher requirements for automobiles. High-strength steel is one of the effective ways to achieve automotive lightweighting and improve structural strength. However, high-strength steel is difficult to form and suffers from severe springback, making it difficult to process using traditional cold stamping. Hot forming technology has therefore emerged. It involves heating sheets to a high temperature and then stamping them using a die. This article will help you understand the hot forming stamping line.

Components

1. Destacking System

(The following are truss destacking and 6-axis robot destacking.)

(The following are truss destacking and 6-axis robot destacking.)

The destacking system consists of the loading trolley and manipulator, which is responsible for separating sheets from the stack and transferring them to the next work area. A truss destacking system or a 6-axis robot can be used for destacking.

2. Heating Furnace

(Shuttle cars for box furnace.)

(Shuttle cars for box furnace.)

Heating furnaces can be divided into box furnaces and roller furnaces. Box furnaces additionally require shuttle cars to receive and transfer sheets. Roller furnaces have a longer furnace body and typically use a roller conveyor system consisting of multiple rollers to achieve continuous transfer of the sheets within the furnace.

3. Stamping and Transfer

(The following are mold and manipulator.)

(The following are mold and manipulator.)

During stamping, the manipulator is used to load and unload workpieces into the die. Before being placed into the die, the sheet needs to be tapped and positioned, ensuring it can be accurately placed into the die for stamping. The die is designed with a water-cooling system to rapidly cool when the workpiece is being stamped.

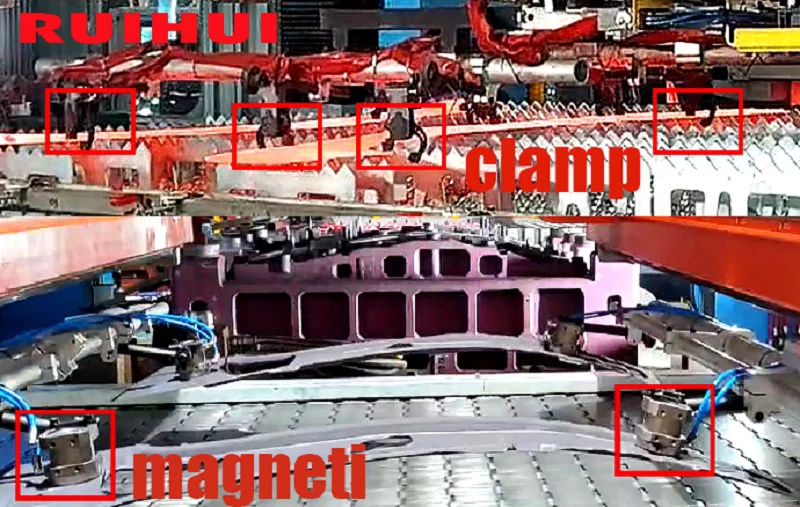

(The clamping hands or magnetic devices.)

(The clamping hands or magnetic devices.)

The heated sheets reach extremely high temperatures, making it impossible for the manipulator to use simple suction cups to grip workpieces; it usually installs clamping hands or magnetic devices.

4. Cooling System

(You can see the cooling system installed on the conveyor belt.)

(You can see the cooling system installed on the conveyor belt.)

The cooling system is installed above the finished-part conveyor and consists of multiple fans. It helps further reduce the temperature of the production, making subsequent manual collection easier.

5. Conveyor Belt

Typically, a steel strip conveyor belt is used, offering higher heat resistance and a longer service life.

Main Features

1. Effective for high-strength sheets

High-strength sheet metal has a high yield strength, making it difficult to stamp and potentially prone to springback. Heating at high temperatures improves the material's flowability and ductility, making it easier to form.

2. Higher Product Strength

When a sheet is heated to a high temperature, its microstructure transforms into austenite. Subsequent rapid cooling of the high-temperature sheet can transform its microstructure into martensite, thereby further increasing the production's strength.

Based on different heating furnaces, RUIHUI designed the box furnace hot forming stamping lines and roller furnace hot forming stamping lines. These two types of production lines offer excellent processing results, a high degree of automation. If you are interested in hot forming stamping or have any questions, you can contact us. Thank you for reading.

(The box furnace hot forming stamping line.)

(The roller furnace hot forming stamping line.)

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.