Difference Between Progressive Die Stamping and Transfer Die Stamping

In metal stamping, progressive die stamping and transfer die stamping are two typical production lines. They focus on different aspects. Understanding their differences helps in selecting the right processing method and improving efficiency. Now, let's explore them together.

Processing Principle

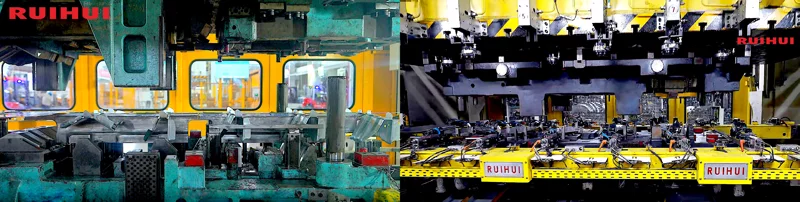

Progressive Die Stamping starts with coil material. After being processed through an decoiler straightener feeder machine, the coil is fed into the press for stamping. A single press is equipped with one progressive die, which contains multiple stations inside the same die to complete different processing steps.

Transfer Die Stamping starts with sheet material. The sheets are extracted by a destacking system (or use a shearing machine while feeding), and a 3-axis transfer robot moves the material between stations inside the press to complete the stamping process. A single press is equipped with multiple separate dies, each performing a different operation.

Feature Comparison

1. Speed

In progressive die stamping, feeding is performed by a feeder, which operates with a simple, continuous motion suitable for high-speed production. Transfer die stamping relies on a robot to complete a series of actions—gripping, lifting, shifting, lowering, and placing the workpiece, so its production speed is not fast.

2. Forming Capability

Progressive dies have tightly arranged stations, and the limited internal space restricts their forming capability. Additionally, in a progressive die, the material is not separated into individual parts until the final station. This means that if the forming shape is too complex (such as deep drawing), it may interfere with feeding.

In comparison, transfer die stamping provides ample space, and the manipulator can freely handle the workpiece, enabling the processing of parts with more complex geometries.

| Feature | Progressive Die | Transfer Die |

| Flexibility | Average | High |

| Speed | Fast | Moderate |

| Forming Capability | Average | Excellent |

Application Scenarios

The progressive die is suitable for processing small and structurally simple parts. Main examples: electronic hardware parts, small automotive parts. The transfer die is suitable for processing medium-to-thick, medium-to-large, and structurally complex parts. Main examples: large automotive parts, deep-drawn parts.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.