In metal stamping, the decoiler is a core piece of equipment at the front end of coil-processing production lines. It is one of the fundamental machines enabling automated and continuous production. This article will help you understand how decoilers work and the types of decoilers.

Working Principle

A decoiler expands, supports, and tightens the coil via a mandrel. Powered by downstream equipment or its own motor, the coil is unwound at a set speed. During the decoiling, the decoiler coordinates with equipment such as a straightener, feeder, shearing machine, or press machine. It needs to prevent problems such as offsetting, loosening, or pulling.

Component

1. Decoiler Mandrel

(Manual and hydraulic expansion mandrels.)

(Manual and hydraulic expansion mandrels.)

The decoiler mandrel is the core component that carries the coil. After the coil is loaded, the mandrel expands and tightens the inner diameter of the coil, causing it to rotate and complete the unwinding action. Depending on the weight and specifications of the coil, the mandrel can be designed for mechanical or hydraulic expansion.

2. Limit Roller

The limit roller is used to laterally constrain the coil, preventing deviation during the decoiling, and ensuring that the coil remains in the correct centerline position when entering subsequent equipment.

(Decoiler mandrel, limit roller, and pressure arm.)

(Decoiler mandrel, limit roller, and pressure arm.)

3. Pressure Arm

The pressure arm is mainly used to suppress the coil from springing open due to internal stress or tension, especially important in the case of the thicker coil.

4. Loading Trolley

(V-shaped and roller-type trolleys.)

(V-shaped and roller-type trolleys.)

A loading trolley is used to assist in loading coils. It is recommended to use a loading trolley when the weight of the coil exceeds 3T. There are V-type and roller-type trolleys. Use a V-type trolley for coil widths within 1000mm, and a roller-type trolley for widths exceeding 1000mm.

5. Braking Device

(Manual brake of unpowered decoiler.)

(Manual brake of unpowered decoiler.)

(Mandrel hydraulic expansion device and pneumatic brake device of powered decoiler.)

(Mandrel hydraulic expansion device and pneumatic brake device of powered decoiler.)

Braking devices are used to adjust decoiling resistance. They prevent the coil from uncontrollably decoiling due to excessive inertia. Common types include manual brakes and pneumatic brakes,

6. Turning Head Device

The turning head device is mainly configured on double-head decoilers to enable rapid switching between two sets of decoiling shafts. Operation is typically by foot pedal or electric control, allowing the equipment to change rolls without stopping or with only a short pause, thus improving overall production line efficiency.

Machine Type

1. Light Duty Decoiler

(RUIHUI's light-duty decoiler CR-200.)

(RUIHUI's light-duty decoiler CR-200.)

This type of decoiler is generally used in the processing of thin coils in the electronics industry. It can be used as both a decoiler and a take-up machine.

2. Heavy Duty Decoiler

(RUIHUI's heavy-duty decoiler ME-200 and ME-400.)

(RUIHUI's heavy-duty decoiler ME-200 and ME-400.)

Heavy-duty decoilers are common decoilers, and their mandrel is powered. When the coil thickness is close to or exceeds 2.0mm, consider adding a pressure arm. When the weight of the coil exceeds 2T, consider designing the mandrel as a hydraulic expansion.

3. Horizontal Decoiler

(RUIHUI's horizontal decoiler RFU.)

(RUIHUI's horizontal decoiler RFU.)

Horizontal decoilers are typically used for high-speed processing of thin coils. The coil is placed horizontally on a pallet, facilitating loading and allowing multiple coils to be placed simultaneously. Suitable for use with high-speed leveling, feeding, or stamping machines, and widely used in production lines with high cycle.

4. Double-Head Decoiler

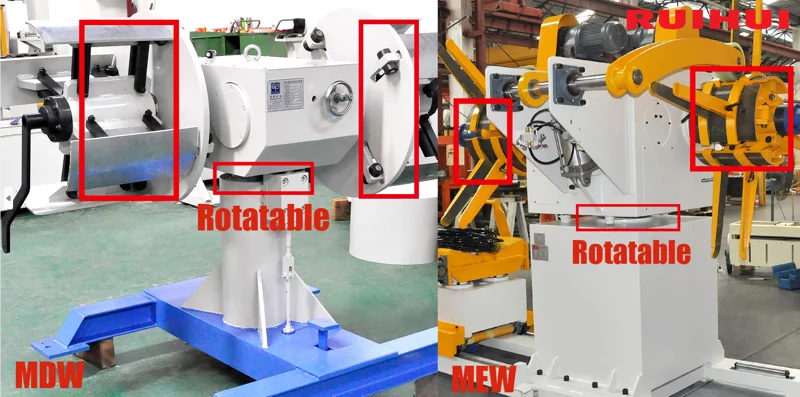

(RUIHUI's powered double-head decoiler MEW and unpowered double-head decoiler MDW.)

(RUIHUI's powered double-head decoiler MEW and unpowered double-head decoiler MDW.)

A double-head decoiler is equipped with two sets of coil mandrels, allowing for simultaneous decoiling on one side and preparation for loading on the other, enabling rapid coil changes and significantly reducing downtime. Depending on production needs, it can be divided into powered and unpowered types, commonly used in stamping or blanking production lines with high continuous production efficiency requirements.

You can see in this video that RUIHUI's feeding line SMAC uses a powered double-head decoiler. If you are interested in decoilers or have any questions, you can contact us. Thank you for reading.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.