What Is the Difference Between Box Furnace Hot Forming and Roller Furnace Hot Forming

Box furnace hot forming and roller furnace hot forming are two common types of hot forming stamping production lines. Although they are of the same type, their different structures lead to different applications. This article will explore their structural differences and how these differences affect the processing results.

Occupied Area

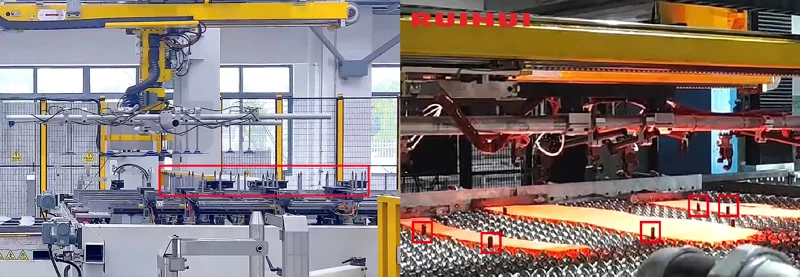

(The floor space occupied by the box furnace and the roller furnace.)

(The floor space occupied by the box furnace and the roller furnace.)

A box furnace is a large heating furnace composed of multiple stacked furnace chambers, making full use of longitudinal space and occupying a moderate footprint. A roller furnace is built on a conveyor belt composed of multiple high-temperature resistant rollers; the furnace body is longer and occupies a larger area.

Heating Form

In a box furnace, sheets are loaded into the furnace chamber and heated in a static state. The temperature of each chamber can be controlled independently. However, every time the sheet is removed, the internal furnace temperature drops, requiring reheating before the next cycle. In contrast, the roller furnace heats sheets while they are placed on a roller conveyor and remain in a relatively dynamic state. During transportation through the furnace, the sheet temperature gradually increases. To maintain a stable heating effect, the roller furnace typically operates with continuous heating.

Tapping Position

In box furnaces, the sheet is fed into and discharged via a shuttle car. Before being heated in the furnace, the sheet must be tapped and centered to ensure accurate removal after heating. After removing the sheet from the furnace, if the mold requires high precision in loading, it needs to be tapped and positioned again.

(Tapping position of box furnace and roller furnace.)

(Tapping position of box furnace and roller furnace.)

In contrast, in roller furnaces, the sheet is continuously conveyed within the furnace via roller conveyors, maintaining a relatively stable overall posture. Therefore, tapping and positioning are only required before loading into the mold.

Production Speed

In each heating cycle, a box furnace requires a shuttle car to load and unload the sheets. In addition, the number of heating stations in a box furnace is limited, so heating must be carried out in batches. Due to these factors, its production speed is relatively moderate. Compared with a box furnace, heating in a roller hearth furnace is performed continuously via roller conveyors. It involves fewer process steps and is subject to fewer limitations on heating stations, resulting in a higher production speed.

| Item | Box Furnace | Roller Furnace |

| Footprint | Moderate | Large |

| Energy Consumption | Higher | High |

| Production Speed | Slower | Slow |

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.